During recent trips to my favorite art gallery and an amazing museum exhibition, I was reminded of how important an artwork’s display is to the overall effect of the art. As I viewed the sculpture collections at this gallery and museum, I noticed how the pedestals on which the artwork rested enhanced my experience of each piece.

If you’ve had a similar experience and wondered how you can achieve the same display and appreciation for your treasured sculpture pieces, look no further than Pease Pedestals. Celebrating 20 years of creating beautiful acrylic fabrication, Pease Pedestals has established itself as a premier U.S. manufacturer of high-end acrylic furniture, fixtures, and accessories.

Founder Patrick Pease and new owner Scott Gordon reveal how the company started, what drives its development, where it is headed today with Gordon at the helm, and—perhaps most important—what Pease Pedestals can do to inspire success in your business.

DECOR Magazine: How was Pease Pedestals founded?

Pease Pedestals: Patrick Pease began working with acrylic in 1979 as co-owner of Carmichael Designs in Palm Springs, California. Carmichael specialized in acrylic furniture design and fabrication. Patrick sold that business in 1995 and returned to his hometown in the Chicago area to raise his family. There, he opened Pease Plastics, again focusing on acrylic fabrication and creating a variety of furniture, display fixtures, accessories, and artwork.

In 1997, Patrick exhibited his spectacular colored acrylic sculptures at Artexpo New York, and he realized that his pedestals were generating as much interest as his artwork. As a result, he created a full line of pedestals, and Pease Pedestals was born.

DM: How did you develop your careers and come into this business?

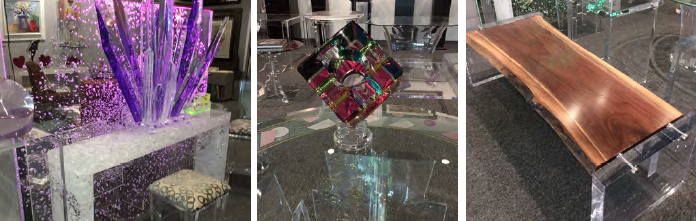

PP: With a background in art, Patrick was drawn to the techniques and creative possibilities of acrylic fabrication. His first and most celebrated pieces were layers of laminated colored acrylic forming magical prismatic sculptures. Needing a way to display the sculptures he created, Patrick made coordinating display pedestals. Galleries began ordering the display pedestals for their artwork, and Patrick soon realized that he could expand beyond the sculptures. The addition of high-end furniture—dining tables, side tables, chairs, barstools, benches, and more—gave the company a full range of products to enhance any decor.

After 35 years of running a successful business, Patrick decided to scale back his involvement and find someone to buy into his business who would continue—and, he hoped, expand on—the legacy that he had built.

Scott has always had a passion for working with his hands. By the age of 10, he had discovered Guillow’s wooden airplane kits—basically a set of plans with a couple of flat sheets of balsa wood from which he could build a fairly complex 3-D airplane that could actually fly. Over time, he expanded and refined his skills, building furniture and remodeling his home. A passion for art led him to open two art galleries in the 1990s, but, with a successful career in film and television, all of these remained merely hobbies—that is, until 2013, when Scott decided to start a second career and do what he loved. He looked for a successful business to buy into that would allow him to be creative and make things with his own hands. Luckily, he found Pease Pedestals just as Patrick was looking to make a move in his career.

Today, Scott and Patrick work side by side, with Scott running all aspects of the business and Patrick advising when needed and occasionally working on a sculpture commission.

DM: What is your vision for the company and the motivation and inspiration behind your product lines?

PP: Our vision is to make Pease Pedestals and its sister company, Pease Plastics, the premier U.S. manufacturers of high-end acrylic furniture, fixtures, and accessories. Pease has developed a solid reputation over the years, focusing on innovative design, quality, and service for the most discerning customers. The company wants that legacy to continue. The challenge is to keep all of those attributes at the highest level while scaling up to meet the demand. Deploying the latest technology—laser cutters, engravers, and computer-numerical-control (CNC) routers—certainly helps, but it is our exceptional craftsmen who ultimately maintain our high quality and make innovation happen.

The pedestals are intended to be functional and beautiful yet not overpowering. Because they were originally developed to showcase Patrick’s acrylic art, many of them incorporated lighting, along with motors and turntables. The original designs have evolved over the years to our current line. We also create custom designs, and popular custom features often migrate to our standard line. We are continuing to develop new designs, inspired by the latest trends in art and architecture.

DM: What materials and components do you use in your products? What innovations and product features differentiate you from competitors?

PP: At Pease, we use a variety of methods in our construction. Many are common knowledge and similar to woodworking techniques, but we do have a few proprietary methods that set us apart from other acrylic fabricators. In particular, we are known for making beautiful, strong, crystal-clear joints in thick acrylic. Industry professionals constantly compliment us on our joinery, and we have even acted as subcontractors for other acrylic manufacturers to provide them with our high-quality joints. We’ve also developed unique ways of using our laser to build jigs for cutting and shaping, allowing us to make items most acrylic fabricators would only tackle with a CNC.

DM: What are your customers like? Do you have any great customer stories?

PP: Our customers vary quite a bit. Most are galleries or furniture retailers who are in turn dealing with their retail customers. We provide them with all of our resources so that they can offer custom, high-end pedestals as if they were the manufacturers themselves. We work very closely with galleries; they are actually our primary sales force. We also supply a variety of designers and decorators, as well as a few of our own retail customers. We cater to a high-end, discerning clientele, but we also provide a full range of pedestals, including simple boxes and display cases.

One of our favorite stories involves a designer who was so pleased with the acrylic furniture and decorative items that we had made for her that she sent us a very generous gift. In most companies it works the other way around! Somehow, we’ve managed to attract the most amazing, appreciative, and loyal clientele. Who could ask for more?

DM: How many people do you employ?

PP: We have 27 employees, and every one of them counts. We believe in taking very good care of our staff; they are our most important asset. Each is an expert at what he or she does, and is valued by everyone within the company. We’re very proud to provide them with good wages, paid vacation and sick time, a health plan, life insurance, and a 401(k) plan with matching funds.

In addition, we support the community where we all live and work. Many of our regular customers are local, so their causes often become our causes. We donate money, goods, and services to local charities. We’re also members of the local chamber of commerce and some neighboring towns’ chambers of commerce. We think this completes a circle of taking care and giving back, and we have been rewarded with loyal employees and loyal customers.

DM: What can you tell us about product development? What’s on the drawing board?

PP: Our customer base includes many leading designers and decorators, so we’re always participating in the latest trends. The development of new products at Pease Pedestals is constant and ongoing. Some designs begin as modifications to existing pedestals, and others are completely new creations. Inspiration comes from a variety of sources—perhaps an amazing work of art or a bold example of architecture.

Inspiration can also come from new technology. For example, although we have no specific plans to introduce any new models in the coming year, it’s quite possible that our ongoing migration from halogen- and fluorescent-light sources to LEDs could result in new designs. Our growing use of lasers and CNC routers also opens up new possibilities beyond what we could do with traditional tools. We’re not only able to manufacture in a better way, we’re also often able to add new aspects to the design.

DM: Do you have anything else to tell our readers?

PP: Even after all these years, it’s great to see the business growing and thriving. We do it through building partnerships internally and externally: with our staff, our customers, our community, our industry, every point of contact.

We’re excited about what we have. What we see in our customers is love for what we do and how we do it. How can you beat that?

For more about Pease Pedestals, visit peasepedestals.com.

NO COMMENT